SQL PRODUCTION

Manufacturing Process Planning (MRP) & Costing Control

SQL MRP Software provides real-time insight into production line efficiency and productivity, assists with cost calculations, identifies variances, and controls work in progress. Additionally, it can customize any type of job sheet to make sure all your projects have the right specifications. This makes SQL MRP Software a great choice for businesses that need to create unique job sheets for their projects.

By utilizing SQL MRP Software, businesses can streamline their production and manufacturing processes to stay ahead of the competition, leveraging the newest technology to maximize efficiency.

Production/manufacturing included the following major functionalities:

- Bill of Materials

- Job Order + Stock Reorder Advice (for material resource planning)

- Assembly / Disassembly

Best production/manufacturing reports are locked in the system itself including:

- BOM Trees

- BOM Material Usage

- BOM Planner

- BOM Assembly Detail Listing

- Outstanding Job Order Listing with materials shortage summary

- BOM Wastage

- Work in Progress Report

- Stock Assembly-JO vs AS Variance

Recipes Master

Bill of Material (BOM) is a comprehensive inventory of the raw materials, parts, components or sub-assembly required to manufacture/assemble a product. Recall recipes to generate Job Order and plan the materials availability daily or weekly. Comparison with a standard and actual for cost and qty delivered a variance report to assist QC in making decisions.

Product Costing

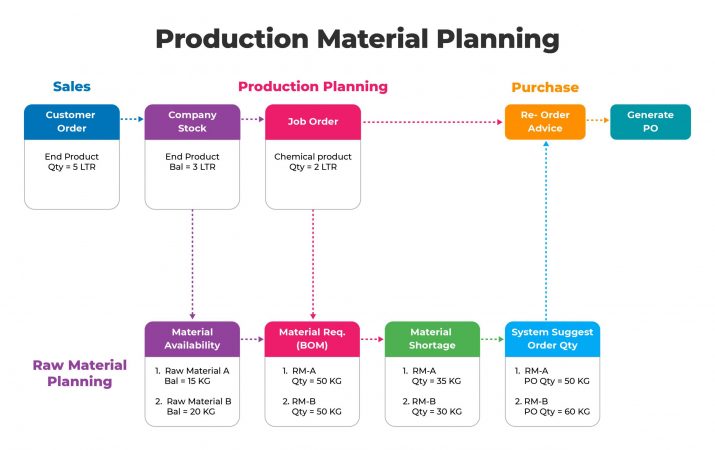

Production Materials Planning

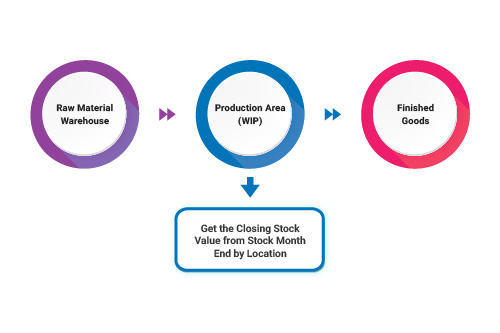

Work in Progress Control

Traceability by Batch Production

Benefits Of Using SQL Production MRP

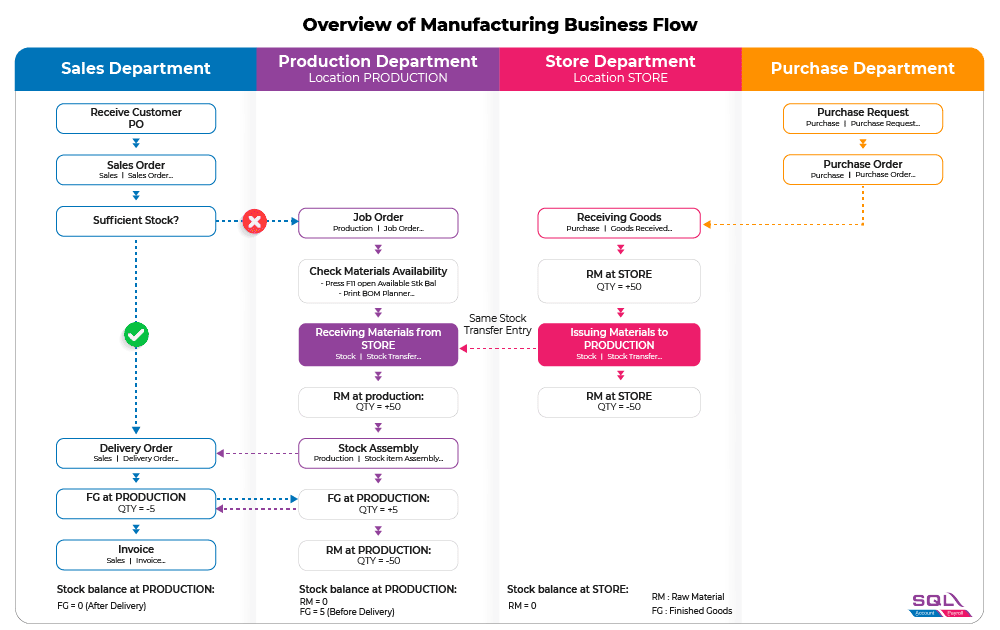

The sales coordinator can update customer orders and sync the sales order into Job Orders for production to plan. The system will auto-calculate materials required based on the recipes and at the same time check the availability of the materials to allow production to carry on to meet the customer’s expected delivery date. With the real-time stock data from other departments, the purchaser is able to retrieve it to plan the materials to order from the supplier at the expected to-be-received date.

Minimise the shortage of materials case

System capable to analyse the materials required based on the production plan or customer orders delivery date.

Reduce unseen material losses

A good planning system should provide the real time stock data to avoid unnecessary loss of stocks due to over stock kept and expired.

Optimize the stock level as possible

A good planning system should provide the real time stock data to avoid unnecessary loss of stocks due to over stock kept and expired.